View Mobile Number

- GST NO. : 27AAKCD0527G1ZT

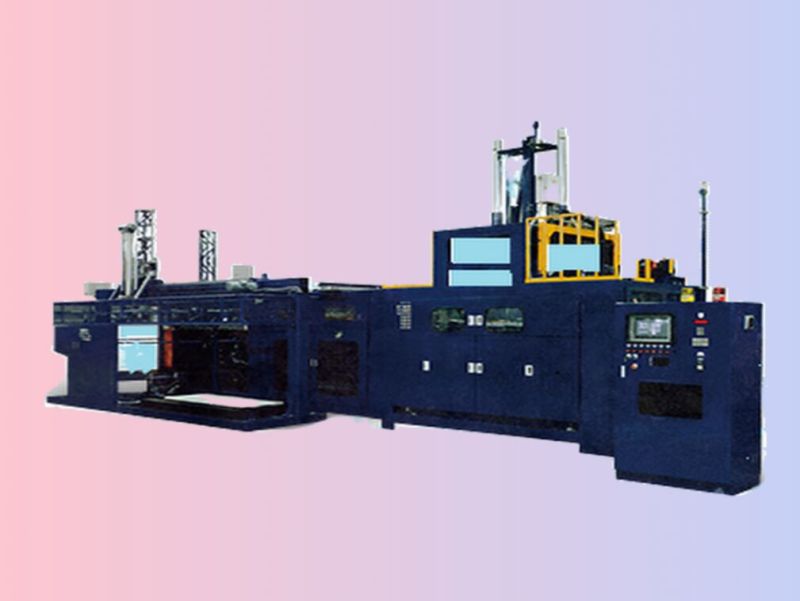

Vacuum Forming Machines

Leading Manufacturers, Exporters and Wholesaler of SVF Series Special Purpose Vacuum Forming Machine, Special Purpose Vacuum Double Station Forming Machine and CVF Series Contineous Vacuum Forming Machine from Nashik.

| Business Type | Manufacturer, Supplier, Trader |

| Country of Origin | India |

| Warranty | 1 Year |

| Type | Vacuum Forming Machine |

| Driven Type | Electric |

| Usage | Industrial |

| Feature | Pneumatic/Servo Mechanism, Intellectual Machine and Heating control system , High energy saving |

| Software Attached | Intelsoft :- Advance Machine and Heating Control Software |

| Payment Terms | Other |

Preferred Buyer From

| Location | Worldwide |

Special Purpose Forming Vacuum Machine

Our Special Forming Vacuum Machine is a highly customizable solution designed to meet unique production requirements across various industries. This advanced vacuum forming system is engineered for precision and efficiency and is tailored to handle complex shapes, materials, and sizes, ensuring superior quality and performance.

Key Features:- Custom Design: Fully adaptable to specific production needs, including mold size, heating zones, and automation levels.

- High-Performance Vacuum System: Ensures precise forming with optimal material distribution.

- Versatile Material Compatibility: Suitable for ABS, PVC, PET, Acrylic, and other thermoplastics.

- User-Friendly Operation: Intuitive controls with digital interface for easy adjustments and monitoring.

- Energy Efficient: Advanced heating and vacuum technology to reduce energy consumption.

- Robust Construction: Built with durable materials for long-lasting operation and minimal maintenance.

- Heating Control- Sandwich heating system with options of Infrared / quartz / high response IR heaters to optimize energy consumption

- Machine Monitoring - online monitoring , Data processing & OEE reports ( Indutry 4.0).

- Price: Not fixed, as each machine is customized based on your specific requirements. Contact us for a tailored quote!

For more information or to discuss your project needs, please feel free to contact us today!

| Business Type | Manufacturer, Exporter, Supplier |

| Warranty | 1 Year |

| Country of Origin | India |

| Driven Type | Electric |

| Usage | Industrial |

| Features | Only Pneumatic |

Preferred Buyer From

| Location | Worldwide |

- 1) Productivity improves (approx. 1.7 times more than single station)

- 2) Reduction in energy per product ( Approx. 40% less than single station).

- Stress relieved robust main framework designed for parallelism to withstand continuous operations.

- Machine incorporated with pre-blow.

- Blown-bubble height mechanism by precision sensor.

- Automatic sheet clamping and de-clamping mechanisms.

- Sandwich heating system with options of Infrared / quartz / high response to optimize energy consumption

- Man- machine interface with touch screen and safety interlocks

- High speed cooling blowers ensures faster cooling of article

- Provision for mold cooling.

- Machine is designed in line with CE guidelines.

| Business Type | Manufacturer, Exporter, Supplier |

| Driven Type | Electric |

| Warranty | 1 Year |

| Country of Origin | India |

| Usage | Industrial |

| Feature | Easy To Operate |

| Software Attached | Intelsoft :- Advance Machine and Heating Control Software |

Preferred Buyer From

| Location | Worldwide |

The continuous vacuum forming station design allows any nominal size of 500 x 500 mm upwards to 2000 x 1500 mm max. The cut sheet, pick in place to transport chain then it will move to heating station then forming station, ejection of formed product automatically.

This machine offers you higher productivity and less labor cost because loading and unloading of sheet operation is automated.- The inline type design of machine contains - sheet pickup, heating and forming help us to reduce cycle time and man power.

- Reduction of labor cost and in-process inventory by automation.

- Stress relieved robust main framework designed for parallelism to withstand continuous operations.

- Machine incorporated with pre-blow and plug assist.

- Blown-bubble height & sag control mechanism by precision sensor.

- Automatic sheet clamping and de-clamping mechanisms.

- Sandwich heating system with options of Infrared / quartz / high response IR heaters to optimize energy consumption

- Man- machine interface with touch screen and safety interlocks

- High speed cooling blowers ensures faster cooling of article.

- Provision for mold cooling.

- Machine is designed in line with CE guidelines.

- Auto clamping for mold & plug

- Mold temperature control system

- Adjustable bottom clamp & top clamp

- Auto sheet / roll loading & product unloading

- Quartz & high-speed heaters

- Quick mold loading